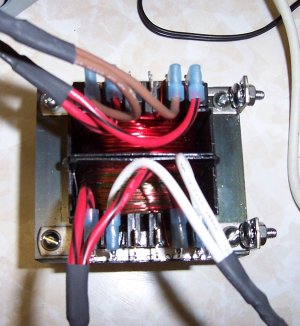

Damn That's a Big Transformer!

Now that's a great can cooler, but it needs something heavy-duty to run it. Enter the huge Supply O' Doom! It uses a large 10VAC 175VA transformer that I got by chance for free. This was going to be the most expensive part of the cooler, but luck was good and I got it free. The power supply is basic, just a bridge rectifier (on temporary) heatsink, filter cap, and the big transformer. I will be adding safety features to it later.

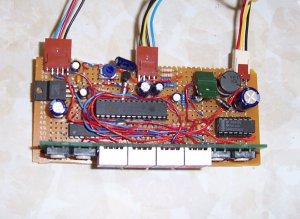

The power supply connected to cooler guts

Not a whole lot to say. This is the complete dealie in an early stage of testing. I want to make/buy a small box for the power supply eventually and make a box for the cooling portion. It will be made out of plexi and then filled with spray insulating foam around the can cooling portion. The assembly is laying on its side to let air get into the fan, and so water can drip off instead of down on the FET and such.

The bridge is on this "heatsink" which is just a project case that had a convenient hole in it. It is passing about 8 to 10 amps when the cooler is running full tilt. It dissipates around 10-12 watts which is quite a bit of heat. A synchronous rectifier might be a better option at a later date.

The business end of the fan. This sucker sounds like a jet engine when it's running full blast! Fortunately the PIC can PWM the fan so it doesn't run so fast.

Without insulation, water will condense like crazy on the peltiers. This is why insulation is an absolute MUST for any project like this. There was a significant puddle under the cooler after running it 10 minutes. The controller was maintaining the temperature on the cold side at 7 degrees C during the 10 minute test run. With insulation around the can cooling portion, it should get colder faster and be able to pump more heat out of the drink. I want my drinks to have that "just opened" taste/temperature 2 hours later :-)

This is the old controller I made. I am in the process of making a new one that is much smaller and better. It will have an ADC for temperature reading since the PIC's ADC sucks shit thru a straw. The reading jumps around like a frog on crack, from 4 degrees C to 6.5 then maybe 5. It isn't my grounding or anything; it is just a shitty ADC (microchip even admits it doesn't meet their data sheet specs!)

|